Krenar Komoni wants to be able to track every shipment, everywhere in the world. And he’s well on his way to doing it.

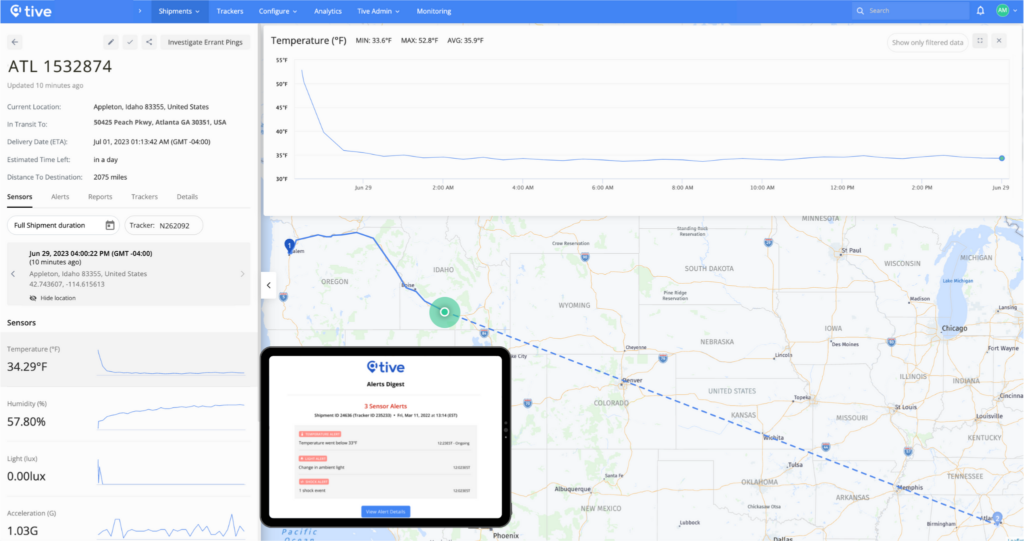

He’s had the entrepreneurship bug since he was a teen and has been fascinated by wireless technologies since he was in college. The two passions came together over his father-in-law’s dinner table (of all places) and gave him the idea that became Tive: cellular-enabled, battery-efficient, low-cost trackers that not only provide real-time location coordinates but also provide important shipment data like temperature, humidity, light, and movement information.

Komoni grew up in Kosovo and came to the United States when he was 17 as a high school exchange student. But he knew he wanted to be an entrepreneur well before he arrived in this country. Starting in the mid-1990s, when his father first brought home a computer, Komoni began learning an application called 3D Studio Max, which built 3D animations. When he saw a job posting in the newspaper for a new television station that was starting in Kosovo, KohaVision TV (KTV), he was interested. Everything for the station was new — new staff, new reporters, new sets and titles and logos. Komoni got a job creating all of its 3D animations. A few months later, they were on the air, and he was hooked. “That concept of creating something out of nothing,” he says, “I thought, I’m always going to do this.”

After high school, Komoni continued his education in the United States. He studied computer engineering and mathematics at Norwich University, a private military college in Vermont. Professors wore uniforms, as did most of the students, and there he learned discipline and leadership skills. He earned a master’s in electrical engineering at Tufts University.

We spoke to Komoni recently about his passion for wireless, his accidental journey into the supply chain industry, and his vision for a future where every single shipment is tracked.

Tell us about Tive and the idea for global supply chain visibility.

It all started when I got an internship at a company called BitWave Semiconductor, with a Norwich alum. We built the world’s first software-defined radio that did 2G, 3G, 4G, and Wi-Fi, all on a single chip. I got into it at the transistor level, working with and understanding the wireless world, and I loved it. I love building. Wireless is so abstract. For example, we get to communicate here, now, because of wireless. The computer I’m using is connected to Wi-Fi right now, and we don’t even see it. It’s amazing. That’s when I fell in love with wireless and radio frequencies.

Then I stumbled into supply chain logistics, really, through marriage. My wife’s father has a trucking company, and every time I was at his house, he would be on the phone trying to figure out where his drivers were. He was getting up from dinner over and over, making calls, trying to locate drivers. Did they load a shipment? Did they unload? And I realized I could build a better way. I’d make a GPS tracker, connect it through a cellular network, and put it in on his trucks.

But there was a lot of competition in tracking trucks. One of the truck drivers showed me a temperature sensor that went on top of a pallet. I asked how they got the data from it, and he explained that at the end of the shipment, they have to plug it into a computer to download the data. And I knew that was too late, so I built the tracker with cellular connectivity included. I added a battery to it and made it battery-efficient, so we could put it on the pallet and in the truck, to get data in real time. Then I added a temperature sensor, an accelerometer, and a humidity sensor, and all of that data was captured in real time. That’s where the whole idea started.

Is that how you differ from other solutions on the market today?

We were the first to build a tracker that offered all that data, and that had the longest battery life in the market.

Today, at the cost we’re available in the market, we have the most accurate location data because we use GPS, Wi-Fi positioning (through Qualcomm Aware™), and cellular triangulation. The others only use cellular triangulation. We’ve been able to build a non-lithium-based tracker with nickel metal-hydrate batteries, because our power performance is more efficient and superior to competitors, and we’ve built a tracker that’s smaller in size and can last for several months. We also have easy-to-use software with a great user experience that provides analytics and API integrations to transportation management systems. And we have an amazing customer support and sales team.

We’ve raised $80 million to date from multiple funding rounds. The last one was a series B. We have more than 600 customers and help them every day, whether it’s tracking strawberries and blueberries, or vaccines and Covid test kits, or servers, vacuum cleaners, avocados, or salads. It’s pretty amazing!

Where do you see the supply chain ecosystem going in 10 years, and how does your vision for Tive fit into that?

Having complete visibility of every single shipment in the world will soon become a requirement. One way to get it is on the shipping industry side, by connecting every single asset that’s moving products to the internet—that’s the trucks, trailers, containers, vessels, trains, everything. But the challenge there is that there’s a ton of fragmentation in the shipping industry, and there are a lot of integrations that need to happen to get that data from the shippers.

The better way to get 100 percent visibility — the only way, I believe — is by placing IoT devices like trackers, not on the assets that are moving the shipments, but on every single shipment.

In 10 years, the cost of making chips and the cost of connectivity is going to follow Moore’s Law on processing power, and Koomey’s Law on energy efficiency, and Metcalfe’s Law on network effects, and together that will drive the cost of each tracker to less than $10, where it makes complete sense for them to be on every single shipment. And as Tive grows, we’re going to create such a large global network that we’ll become the world’s largest and most important provider of supply chain visibility utilizing proprietary data generated by best-in-class hardware and connectivity.

How will 5G and then 6G factor into that?

When it comes to tracking shipments, the goal is to use the least amount of bandwidth for the shortest amount of time. Where 5G and then 6G helps is with new base stations that are being installed in cell towers. Instead of managing with whatever the limit was with 2G and 3G, possibly a few thousand connections, they would be able to handle hundreds of thousands of connections to hundreds of thousands of assets at any given time, each with short bursts of information. 5G and 6G will also have power consumption benefits allowing you to transmit more data during a shorter amount of time with the least amount of energy. That’s the exciting part for Tive, using low power with small amounts of data being transmitted, that will help us put more trackers around the world. 5G and 6G will enable us to accomplish our vision of tracking every single shipment.

What advantages has Qualcomm Ventures been able to provide as an investor?

The biggest benefit we’ve gotten from Qualcomm Ventures is proximity to the engineers who are working on the next generation of products at Qualcomm Incorporated. Having the ability to communicate with them and understand Qualcomm’s vision for wireless, on location technology and connectivity and where it’s going, has been really helpful. When we look out five or ten years from now, we need to understand that companies like Qualcomm are going to be innovating alongside us as we try to put trackers on every single shipment out there.

You’ve had a long career in data analytics and logistics. What have you learned in previous roles that have helped in founding Tive?

In my first job, I was an engineer designing RF chipsets, and I was working on just a small portion of the transmitter. The product schedule kept getting delayed for various reasons. So, I went to the CTO and asked him for permission to try to understand the parts that the other engineers were working on, so I could understand how long the whole project would take. He asked me why I wasn’t just going and doing that, and I said because I didn’t have the authority. I was 20 or 21 years old at the time, and he said, “Just go do it.”

I took that advice and learned what the engineers were all working on. I built a spreadsheet, I understood the entire project, and eventually my spreadsheet was off by only two weeks on the project end date (chip tape-out). That was a valuable experience to learn at a very young age. The lesson was, if you want to do something, if you want to lead, nobody’s going to give you permission. You just have to do it. Build things. Start a company. And don’t wait too long.

What advice do you give to the next generation of entrepreneurs and founders?

There is no right time. People say, when my family is in the right situation, or when I buy a house, or two or three years from now, when I have more experience. There’s always some reason why they don’t want to start the company today. I don’t think there is such a thing as the right time. If you’re ready to go, just do it. The best time is right now, because the more time you buy yourself by getting started, the better it is, and the more time you have to succeed. It took me eight and a half years to get here. If I’d started two years later, I don’t think we would be where we are today.

I learned a lot of lessons in those first two years. If I was delayed by two years, maybe somebody else would’ve learned those lessons and been ahead of me.

What is the greatest lesson that you feel like you’ve learned as a founder and CEO?

It’s the thing I learned two years in. As an entrepreneur and as a CEO, I learned that the fastest way to figure out if you’re doing the right thing is to pick up the phone and cold-call prospects — and as many as you can. I learned that lesson when we were running out of money and had $20,000 in the bank, and I had to go and raise money again. As we were going through that process, we just started cold calling, emailing prospects, trying to understand what they would buy. And if you’re always available to call and learn from customers — especially tech entrepreneurs, because we all think our tech is the best, and sometimes we need to hear why maybe it isn’t — you’ll really know whether your product is doing the right thing, or you need to change. You’ll learn that there’s competition. You’ll learn that customers want something different.

I realized that in this industry, and I think in a lot of other industries, maybe the product-market fit works. Ours did. But there’s another thing, product-market-price fit. When you add the price to the mix, that really opens amazing doors, because everybody wants a GPS tracker, but nobody wants a $200 tracker. Once you sell it for $50, for $40, then suddenly the doors open. Can you imagine what’s going to happen when it’s $10?

Is there someone you think has influenced you most in your career?

Burbuqe Rushiti

My mom. She passed away in 2019. She was 58 years old.

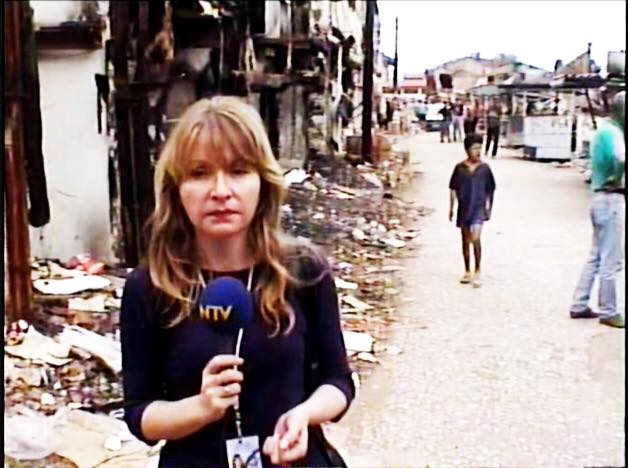

She is where I really learned about entrepreneurship. I grew up in Kosovo. When the war started, both my mom and dad were kicked out of their jobs. My mom was extremely brave. She started giving courses to teach kids English. She would teach kids at our kitchen table, on weekends. They would pay $5 or $10 a month. That was entrepreneurship. My mom built something; she figured out a way to make money out of nothing. She built a business in our kitchen.

One day she was listening to a Turkish radio. She didn’t know perfect Turkish, but she knew Turkish. She called the radio station and said, “Hey, you guys were wrong about this reporting. This is what actually happened.” They put her live on a radio show, and she became a journalist on the radio and then a journalist at a TV station in Turkey — while she was still teaching these courses in English, in our kitchen. Entrepreneurship and bravery to take action when you see something, is inspiring — I am always going to be action-oriented like her.

* All opinions expressed in this blog are solely from Krenar Komoni